Master inventory forecasting for cost-effective stock management

Inventory management is a tight-rope balancing act. Ordering too much leaves you with excess stock tying up capital and warehouse space. Ordering too little puts you at risk of running out of stock, leading to stockouts, missed sales, and frustrated customers. Bad inventory forecasting means storage fees, excess inventory, waste from unsold goods, and operational inefficiencies that eat into profits.

Distributors need to get stock levels right to have the right stock, at the right time, and in the correct order quantity. This is where inventory forecasting comes in. With the right data-driven approach, distributors can forecast demand more accurately, get stock levels right, and stay operationally efficient. This article discusses inventory forecasting, its benefits, how fluctuating conditions impact forecasts, and why having up-to-date data is key to making agile inventory decisions.

What is inventory forecasting?

Inventory forecasting uses historical sales data, market trends, and predictive analytics to estimate future product demand. By analyzing past sales performance and relevant external factors through trend forecasting, businesses can predict how much stock they need over a time period.

Accurate inventory forecasting takes into account various data points, including:

-

Sales history – Analyzing past trends to forecast future sales.

-

Lead time and maximum lead time – Understanding how long it takes (average lead time) to restock items.

-

Market research and trends – Monitoring industry trends and consumer demand.

-

External factors – Considering seasonality, tariffs, and economic conditions.

-

Safety stock levels – Having backup stock to prevent stockouts during demand fluctuations.

With good inventory forecasting methods, distributors can prepare for demand volatility and reduce stockouts, minimize overstock and get purchasing decisions right. Ultimately, this improves cash flow and profitability.

How inventory forecasting helps distributors

Inventory forecasting is where distributors really get an edge by simplifying inventory control, reducing carrying costs, and improving customer satisfaction. Accurate demand forecasting helps you maintain optimal stock levels—without excess or shortages. This means lower holding costs and better cash flow, while meeting customer demand when and where it counts.

High stock levels tie up working capital and increase carrying costs. Forecasting helps you keep your inventory lean, cutting warehousing expenses, insurance costs, and the risk of product going stale. Strong supplier relationships are at the heart of efficient inventory management and can mean better lead times and cost savings. By anticipating future demand and planning purchase orders strategically, you can negotiate better prices with suppliers and reduce the risk of supply chain disruptions.

When stock runs out, you lose sales—not to mention the impact stockouts can have on customer satisfaction. Forecasting tools help you have the right products when customers want them. That means better service levels, customer retention, and repeat business. Inventory forecasting also gives you a clearer view of future sales trends. That means you can allocate resources effectively and avoid unnecessary stock investments.

Mark Law, IT Director at Hayley Group, highlights the impact of effective inventory forecasting on daily inventory movements: " Phocas has helped us to analyze stock that isn't moving or is moving slowly, so we can move stock around to make the best use of it...It ensures timely adjustments to orders and fosters a more responsive supply chain ecosystem.”

How changing conditions affect inventory forecasts

Inventory forecasting isn’t static—many internal and external factors influence it. Distributors must account for these fluctuations to keep their forecasts accurate and relevant. Incorporating real-time data analytics into inventory forecasting can significantly enhance a distributor's ability to manage seasonal demand fluctuations, like eCommerce businesses stocking up before the holiday season or agricultural suppliers preparing for planting cycles. If forecasting techniques don’t account for these shifts, businesses may end up overstocking or running out of stock—and lose revenue or incur excessive inventory costs.

Pool Pro, a distributor of pool supplies, transitioned from using spreadsheets to a data analytics solution, which streamlined their inventory management. Managing Director Sean Ralph noted that the previous method was 'very time-consuming.' With the new system, they can adapt quickly to weather patterns and adjust their product mix or stock holdings accordingly. “Using Phocas makes me feel like I’m in control of my data,” Sean says.

Import and export tariffs can impact inventory costs and availability. A sudden tariff increase can increase pricing for certain products, while regulation changes can cause supply chain disruptions. Distributors need to factor these elements into their forecasts to adjust their procurement strategies. Fluctuations in consumer demand, inflation, or recession will also impact product demand. A slowing economy means lower sales; an economic boom means more demand. Businesses that track economic trends and adjust their forecasting models accordingly will manage stock better.

Unexpected natural disasters, geopolitical events, or supplier shutdowns can cause inventory shortages, too. Distributors with flexible, data-driven forecasting can adapt quickly, find alternative suppliers, and adjust inventory levels as needed.

Why access to real-time data matters

Real-time inventory data is key to making decisions. Traditional forecasting models based on historical data alone are no longer enough. Businesses need to use up-to-date information to react to changes.

Distributors can monitor inventory needs and levels by integrating inventory management software with live tracking. This prevents overstocking and stockouts by giving instant visibility into how much inventory is needed and when. These modern inventory management systems can automate stock replenishment based on predictive analytics. By setting a reorder point based on real-time data, distributors can maintain optimal inventory levels without manual intervention, reducing errors and saving time.

Harvey Lewis, General Manager of Caprice Australia, highlights the significance of data-driven inventory planning:

"Our data in Phocas, combined with our retail partners' sales data, lets us plan inventory to place the right commitments with our resources and vendors overseas. This allows us to make sure we're holding the right number of weeks' stock domestically to meet demand. It ensures that we’re running a profitable business."

Advanced inventory forecasting tools powered by artificial intelligence (AI) and machine learning algorithms analyse huge amounts of data to find patterns. Using forecasting tools and inventory tracking, inventory planners can assess demand more accurately based on real-time market conditions. This means procurement and replenishment strategies align with expected customer demand fluctuations and reduce waste and inefficiencies. New products can be added to inventory forecasts using qualitative forecasting techniques and market trends analysis to predict popularity. For example, if customer orders for a particular SKU suddenly surge due to a viral trend or competitor stockout, you can adjust your forecasting process and procurement strategy immediately to meet the demand.

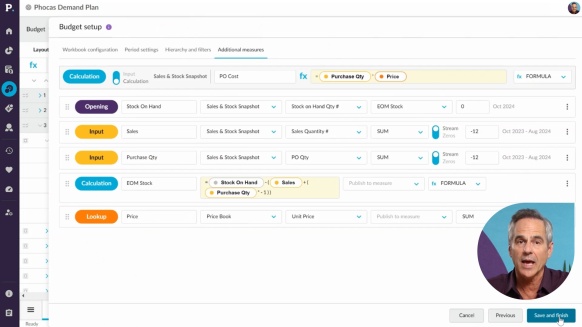

Inventory optimization with BI and FP&A

With business intelligence (BI) and financial planning & analysis (FP&A) software, you get deep insights into sales trends, demand patterns, and supply chain performance through data analysis – everything you need to optimize inventory planning and improve demand forecasting. The software also seamlessly integrates with existing inventory management systems and ERP platforms, offering real-time insights into inventory tracking and replenishment data. Combining multiple data sources can create more accurate inventory forecasts and reduce uncertainty.

Advanced forecasting tools, including graphical forecasting, qualitative forecasting, and quantitative forecasting, ensure the correct number of units is on hand at the right time. BI and FP&A software visually represent inventory trends, so you can quickly assess seasonal fluctuations and necessary stock level adjustments. Using FP&A tools, you can optimize inventory turnover, reduce carrying costs, and maintain a healthy cash flow by investing in the right inventory at the right time.

Forecasting is the backbone of good inventory management and with historical sales data, predictive analytics and real-time insights business people can turn inventory faster. This helps to reduce costs and improve customer satisfaction. But forecasting isn’t a one-time exercise – it requires ongoing adjustments based on changing market trends, regulatory changes, and external disruptions. With up-to-date data and the functionality of smart forecasting tools, distributors can streamline inventory planning, make informed decisions, and stay ahead in fast-changing markets.

Katrina is a professional writer with a decade of experience in business and tech. She explains how data can work for business people and finance teams without all the tech jargon.

5 key FP&A trends for 2025

The role of the CFO is evolving rapidly, extending beyond traditional financial stewardship to encompass business partnering, operational oversight and technological innovation. A 2024 Sage study of over 1,200 global finance leaders reinforces this transformation:

Read more

Safety stock calculations for distributors

Effective inventory management is critical for distributors to meet customer demand, prevent stockouts, and optimize supply chain efficiency. At the heart of your inventory strategy is safety stock levels like a library stocking multiple copies of favorite titles, so if several people borrow the same book at once, there's still a copy available for the next reader. A distributor stocks extra product as well, to maintain product availability and customer satisfaction but striking the right balance is key to success.

Read more

Demand planning and forecasting

For finance teams in manufacturing, distribution or retail, effective demand planning is critical to meeting customer expectations without tying up cash in excess inventory. When done right, it ensures the right products are available at the right time and in the right quantities.

Read more

Find out how our platform gives you the visibility you need to get more done.

Get your demo today