How business intelligence improves supply chain management

Supply chain managers have been up against high transportation costs, inflation and rising prices since the pandemic and while the situation has stabilised for some industries - most have had to change their supply chain processes to manage a more volatile marketplace.

Implementing business intelligence (BI) can significantly enhance a company’s resilience by providing real-time data analytics across the entire supply chain. BI tools consolidate raw data from various sources like erp, crm, finance and the warehouse, allowing businesses to monitor key metrics. This automation of data enables quick identification of bottlenecks or delays, allowing companies to respond promptly to mitigate potential disruptions. With BI, supply chain managers can anticipate issues before they escalate.

Supply chain business intelligence helps manage supplier relationships

A business intelligence platform enhances supplier relationship management by providing a centralized platform to track and analyze supplier performance over time. By consolidating supply chain data from various sources, BI gives businesses one place to evaluate critical supplier metrics like DIFOT(delivery in full on time) and lead times, quality standards, pricing and profitability trends. With real-time insights, supply chain professionals can assess supplier reliability and identify areas for improvement or renegotiation. BI enables a more precise approach to supplier management, where data driven decisions are based on performance kpis, not gut feel and intuition.

BI or supply chain analytics helps businesses identify trends and patterns that can improve collaboration with suppliers. By analyzing data by size of order, demand forecasts, and delivery times, you can communicate more effectively with these stakeholders about future needs and potential risks.

Data-driven insights allows for proactive planning, enabling companies to work with suppliers to adjust lead times, negotiate better terms, or align on contingency plans. BI strengthens supplier relationships by ensuring both parties are aligned on key performance indicators and expectations.

When implementing Phocas business intelligence, we meet supply chain managers who are unaware of the location of their ‘true’ suppliers because the sourcing is done via a third party. The transparency and valuable insights of the purchasing transactions in a BI tool help decision-makers react faster. Tightly managing your direct and indirect suppliers with accurate data brings benefits and efficiencies - in good times and bad.

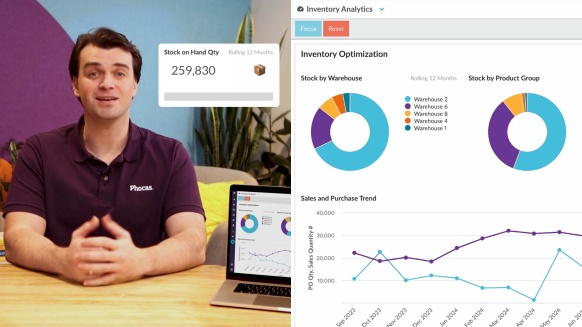

Supply chain business intelligence improves inventory management

As inventory management is a specialized function, it can be overlooked in business, yet, in reality, it involves the entire company. The inventory planner or warehouse staff might have a good system for inventory management but to deal with supply chain disruptions it is necessary for everyone to access this data because they are also affected by the flow of inventory.

With BI you can monitor inventory levels and gain a comprehensive view of all product movements.

BI tools analyze historical data such as sales trends and seasonality, helping businesses forecast demand more accurately and reduce the risk of overstocking or stockouts. By using BI to track inventory metrics like reorder points and safety stock levels, businesses can optimize inventory replenishment and boost customer satisfaction while ensuring they are not holding too much stock

A business intelligence tool is useful to help you determine:

- Purchase orders and purchase receipts – to identify what’s arrived in the warehouse

- Brought-forward value – what stock is still available from the last period

- Identification of likely shortages - based on regular and irregular conditions

- Inter-company movement stock analysis - what departments get priority

- Sales orders, invoices, backorders and forward orders in any combination, sliced & diced to your requirements.

Supply chain business intelligence helps you manage your customers

Truly understanding your customers is critical to running a business and is one of the fundamental benefits of using business intelligence solutions. In regards to disruptions, it might be in your interest to ensure the highly profitable customers get priority.

A comparison between profitability and sales value can help you understand your customer base better using data analysis. As total numbers - sales and profit, it might not be evident that a customer with high sales value isn’t as profitable as you think.

Another critical factor in analyzing customer profitability is the cost of serving individual customers. Use your data to understand your customers’ behaviour and the factors that influence the cost-to-serve.

Pinpoint what customers order standard product versus custom product - can you ask for more time for delivery of the customized version? Can you also delay the small orders because they have not met the 'disruption’ threshold? Work on some new strategies to change the unprofitable behaviour.

You can also use your BI tool to devise a customer response based on territory or industry category - find the areas where customers are still buying because they're least affected by the economic downturn or inefficiencies in the transportation network.

Supply chain business intelligence drives efficiency by optimizing decision-making processes across the supply chain, helping companies maintain seamless workflows even during disruptions. By consolidating and analyzing supply chain data and viewing in BI dashboards, allows supply chain managers to pinpoint and address inefficiencies. Real-time data visualization provides actionable insights, enabling teams to make timely adjustments to keep operations running smoothly and aligned with demand fluctuations. This approach minimizes the risk of costly delays, bottlenecks, and other operational inefficiencies, which directly impacts productivity and cost-effectiveness.

Business intelligence enables a proactive approach to supply chain management, using predictive analytics to forecast challenges and streamline processes. With data-driven insights, supply chain teams can better anticipate supply and demand shifts, allowing them to allocate resources effectively and avoid unnecessary expenses. BI insights can also highlight potential cost-saving measures in sourcing, transportation, and inventory management, empowering companies to better partner with suppliers and improve supply chain operations. By integrating BI solutions with advanced analytics, companies gain a competitive advantage, making their supply chains more adaptable to changing market conditions, ultimately boosting overall operational efficiency.

Katrina is a professional writer with a decade of experience in business and tech. She explains how data can work for business people and finance teams without all the tech jargon.

Using data to plan for the impact of tariffs and further change

Tariffs are here. Whether you're in manufacturing, distribution or retail, it's important to understand how importing from affected countries such as Canada, Mexico or China or chosing local production, can affect your bottom line. We want to encourage you to scenario plan now not retrospectively.

Read more

Essential KPIs every distribution company executive should measure

For mid-market leaders running a wholesale distribution business, data and business intelligence technology are crucial for monitoring financial and operational performance. However, the real value lies in how your team uses the data insights to influence decision-making.

Read more

Demand planning and forecasting

For finance teams in manufacturing, distribution or retail, effective demand planning is critical to meeting customer expectations without tying up cash in excess inventory. When done right, it ensures the right products are available at the right time and in the right quantities.

Read more

The value of integrating financial and operational data

In today’s fast-paced business world, operational efficiency and confident decision-making are key to keeping your competitive edge. However, leveraging financial and operational data to do just that is a significant challenge for many organizations.

Read more

Find out how our platform gives you the visibility you need to get more done.

Get your demo today