Inventory management software

Find out how our platform gives you the visibility you need to get more done.

Get your demo todayWhat is inventory management software?

What is inventory?

What types of data can be analyzed?

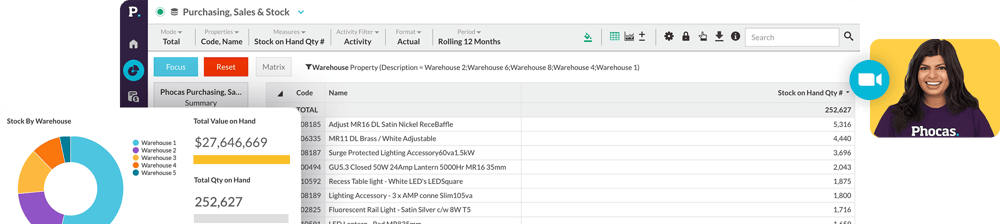

Purchasing data is added to inventory management software so the cost of the raw materials or products can be reviewed, compared and cross referenced.

Sales data is essential so business people can determine the most profitable inventory mix and what inventory or stock is in demand. By reviewing sales data a business can optimize inventory management by knowing the correct amount of inventory that needs to be held for each product line so a business can fulfil all orders without holding too much stock on hand.

Sell thru data is analyzed when distributors sell products through retailers so rely on third party data to determine how products are tracking. Many businesses add this external data into the inventory management software so it can understand product preferences in different channels.

Supplier data is also included in inventory management software so a business has full visibility of all suppliers so strong relationships can be forged and enhance the efficiency of the supply chain.

Finance data from the ERP system helps the inventory management system to accurately determine the value of the stock currently on hand. Read the Johnstone Supply case study.

What industries use the software?

Inventory management is essential in industries where products are made, moved and sold via wholesalers, online or direct to consumers because the raw material or product costs represent a substantial portion of operational revenue.

Manufacturers use inventory management software to reduce waste, manage cashflow and to scale-up a business into new markets. Read the Sistema plastics case study.

Wholesalers of all products use inventory management software to manage its key assets - stock. Wholesalers often have thousands of stock keeping units (SKUs) to manage so need the software to create an orderly flow of goods and operate profitably. Sometimes, vendor managed inventory (VMI) is a supply chain agreement where the supplier takes control of the inventory management decisions for the retailer. Read the American Metals Supply case study.

Retailers use inventory management software to reduce costs and improve customer service. Retailers often have different demand across seasons, so they rely on forecasting inventory levels accurately to meet demand at the appropriate time. Read the Hairhouse case study.

eCommerce can be a hybrid set-up where some operators might not physically manage their own inventory but whether stock is managed or not, eCommerce businesses need to ensure critical inventory levels are kept up to maintain demand. Read the Hein Electric Supply case study.

Why inventory management matters

Key benefits of the software

The benefits of inventory management software flow to both employees and customers. With inventory management software, inventory can be tracked at every step of the process which makes the role of inventory and sales managers more efficient and they can concentrate on better serving customers and providing more accurate advice about stock levels and locations.

Having inventory, customer and product data in one place and being able to analyze it quickly helps track product ordering patterns, which in turn can help avoid missing opportunities or challenges. People can monitor which products key customers are buying, avoid deadstock or overstock situations and enhance data security.

Deadstock and other problems

Poorly managing inventory can eat through your cash flow quickly so it's important to not let inventory get out of control because it can negatively affect your bottom line and stunt business growth.

There are many telltale signs of poorly managed inventory including a perpetual higher cost of inventory and storage, greater likelihood of deadstock, lost customers due to a high level of inaccuracy and problems with orders.

Key features of the software

Increase ROI

Phocas software is industry-specific

Resolve inventory problems

Why choose Phocas software?

Understand the past, operate better today, and plan well for the future