Demand planning and forecasting

For finance teams in manufacturing, distribution or retail, effective demand planning is critical to meeting customer expectations without tying up cash in excess inventory. When done right, it ensures the right products are available at the right time and in the right quantities.

What is demand planning?

Demand planning is a multi-step, cross-functional process to build accurate forecasts of customer demand. It combines historical data, current inventory levels and lead times to determine what products to order or produce and then tracks this forecast against actual sales.

Demand planning involves active efforts to anticipate how demand may change due to market factors, promotional activities or seasonality.

The key differences in demand planning and demand forecasting

Demand planning and demand forecasting are closely related yet distinct processes. Demand forecasting involves predicting future demand for a new product or service based on historical data and statistical models. It is a more data-driven activity that focuses on what is likely to happen based on past trends.

In contrast, demand planning is a more comprehensive, holistic process that includes demand forecasting but goes further by using external data and as well specific information from enterprise resource planning (ERP) systems. Demand planning takes the demand forecast as one input among many, incorporating additional factors such as supply chain constraints (delivery times), resource availability (stock levels) and product lifecycle patterns. It’s a collaborative effort involving different departments to align production, inventory management, sales, and marketing with demand expectations. While demand forecasting provides insights, demand planning drives action.

Why Phocas prioritizies demand planning over demand forecasting

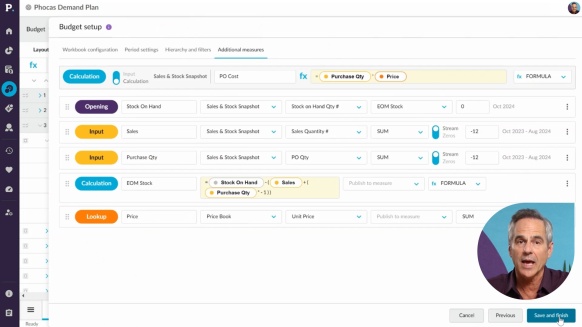

Phocas emphasizes demand planning over simple demand forecasting because demand planning provides a more practical and comprehensive approach for supply chain planning. Phocas goes beyond projecting future demand by helping businesses make plans based on real-time needs and insights. With Phocas, users can leverage their sales budget to spot low stock levels before they become issues, empowering the purchasing team to maintain optimal inventory levels. Phocas also assists in calculating how lead times impact purchasing decisions, allowing businesses to plan purchases with accurate timing.

Phocas enables customers to track their purchasing plans against actual market trends in your sales. This real-time tracking helps ensure that plans remain aligned with actual demand, allowing informed decisions and quick adjustments. By focusing on demand planning as opposed to simple forecasting, Phocas provides a framework that integrates planning with daily operations, allowing you to keep on top of procurement, optimize stock levels, and ensure products never go out of stock.

Industries that rely on demand planning

Demand planning is vital in industries with complex supply chains and variable demand. Some of the industries that benefit most from effective demand planning include:

Manufacturing: Manufacturers rely heavily on demand planning to optimize production schedules, manage raw material procurement, and reduce lead times.

Retail: Retailers need to align inventory levels with consumer demand to avoid stockouts or overstocks, especially during seasonal peaks or sales events.

Wholesale and Distribution: Demand planning helps distributors manage stock levels, transportation needs, and delivery schedules to meet customer demands.

The demand planning process

The demand planning process involves multiple steps and collaboration across departments. Here’s an outline of a typical demand planning workflow:

The foundation of demand planning is data. Demand planners usually rely on a BI and FP+A platform to manage the data from from enterprise resource planning (ERP) systems and create demand and supply chain databases to build the sales forecast and track the actuals associated with supply chain forecasts.

Using the forecasting methods in demand planning tools, users generate demand forecasts and sales forecasts. Multiple forecasting models may be used depending on product type, season or your product portfolio management.

Demand planners collaborate with stakeholders from sales and operations planning S&OP, finance and purchasing to understand the supply chain management process. Each team provides metrics that can affect the forecast accuracy, such as marketing campaign timelines, number of SKUs, sales targets, budget constraints, or production capacity.

The initial forecast is reviewed and adjusted based on feedback from the relevant departments. This step is where demand planning diverges from pure forecasting, as it moves from static demand forecast to a live demand plan.

Once the demand plan matches the organization's resources and capabilities, the finalized demand plan is communicated across departments. This is essential for coordinating production schedules, inventory optimization, procurement, and logistics.

Demand planning is a continuous process. Changes in the market, unexpected events, or new insights may require adjustments. The team tracks actual sales and demand to streamline future planning cycles.

How often should demand plans be updated?

The frequency of updating demand planning depends on the nature of the business, industry disruptions, and volatility of demand. Industries with longer lead times, such as manufacturing, may update plans monthly or quarterly. Retailers or fast-moving consumer goods (FMCG) companies may require weekly updates or even real-time adjustments due to rapidly changing consumer behavior.

Regular updates ensure that the demand plan remains relevant, allowing organizations to stay agile and responsive to changes. Without the right data and technology, many finance teams struggle to demand plan effectively and in a recent Chartered Accountant Survey, 33% of respondents admitted to not being able to demand planning well and a further 23% advised they could do it just, slightly well.

The future of demand planning

The future of demand planning lies in automation, artificial intelligence and real-time data analysis. Advanced analytics and machine learning models in demand planning software are transforming it into a predictive and proactive process. Phocas and similar BI and FP&A platforms focus on building tools that integrate with data from various sources, enabling demand planners to view patterns, spot opportunities, and make real-time adjustments.

With the increased digitization of supply chains, demand planning will become more connected across the entire value chain. We’ll see companies increasingly adopting demand sensing technologies that adjust demand plans based on real-time data inputs related to pricing, such as customer orders, stock levels, and logistics statuses. Collaboration across the supply chain, between suppliers and distribution partners, will also play a larger role, making demand planning a truly integrated process.

Empowering businesses with intuitive data analytics, driving informed decisions for growth and profitability. We make people feel good about data.

Using data to plan for the impact of tariffs and further change

Tariffs are here. Whether you're in manufacturing, distribution or retail, it's important to understand how importing from affected countries such as Canada, Mexico or China or chosing local production, can affect your bottom line. We want to encourage you to scenario plan now not retrospectively.

Read more

Safety stock calculations for distributors

Effective inventory management is critical for distributors to meet customer demand, prevent stockouts, and optimize supply chain efficiency. At the heart of your inventory strategy is safety stock levels like a library stocking multiple copies of favorite titles, so if several people borrow the same book at once, there's still a copy available for the next reader. A distributor stocks extra product as well, to maintain product availability and customer satisfaction but striking the right balance is key to success.

Read more

The value of integrating financial and operational data

In today’s fast-paced business world, operational efficiency and confident decision-making are key to keeping your competitive edge. However, leveraging financial and operational data to do just that is a significant challenge for many organizations.

Read more

Find out how our platform gives you the visibility you need to get more done.

Get your demo today