A critical inventory metric: projected inventory level

With constant streams of data being collected by companies daily, planning is no longer as mysterious as it once was. But it is not a matter of having real-time data that makes forecasting easier; instead, it depends on how the many layers of data are collated and analyzed. When it comes to inventory management with a software solution, it is critical to establish inventory metrics that drive success for the present and future — making projected inventory level a crucial area to monitor.

Read on to learn what projected inventory level is and how it fits with demand forecasting, how to calculate it, and what the benefits are, alongside essential concepts like lead time, safety stock, reorder point, and forecasting techniques. What is projected inventory level?

Projected inventory level (PIL) is a forecasting technique used to determine the inventory needed to fulfil future orders. This method is a necessary addition for businesses that want to get a better sense of the supply chain.

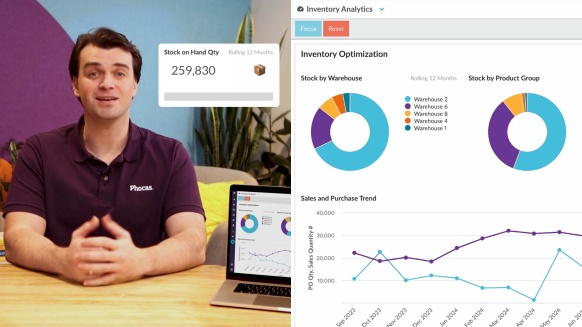

American Metals Supply, an independent wholesaler based out of Springfield, Illinois, is utilizing PIL in their database to gain better visibility into their inventory processes. By feeding this information into a dashboard that shows both current and projected inventory levels, AMS can operate with confidence that they will have on hand the skus they need to meet their customers’ demands.

How to calculate projected inventory level?

It’s a straightforward formula:

Inventory On Hand (OH) + Open Purchase Orders (PO) – Open Sales Orders (SO)

Take the inventory you have on hand at the end of the day, plus all inventory inbound to your system. Then, subtract the outbound inventory from that amount to get the PIL. With the right software solution, this is a simple calculation that can be plugged in and immediately shows results.

Lead time and inventory planning

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is essential for accurate inventory forecasting and ensuring that stock levels align with anticipated demand. Businesses must account for lead time when calculating PIL to avoid disruptions.

Safety stock is a buffer for uncertainty

Safety stock is maintained as extra inventory to prevent stockouts due to demand variability or delays in lead time. Including safety stock in project inventory level calculations ensures businesses can meet unexpected spikes in demand or supply chain delays.

Inventory management and reorder point

Inventory management involves balancing supply and demand efficiently. A crucial aspect is determining the reorder point—the inventory level that triggers a new purchase order. Reorder points integrate lead time, average demand, and safety stock to ensure optimal stock levels.

Quantitative forecasting and Inventory

Quantitative forecasting uses historical sales data and consumer demand fluctuations to predict future demand. Methods like time-series analysis and regression models provide objective insights for inventory planning and projected inventory level.

Sales trends and seasonality

Sales trends and seasonality significantly impact inventory levels. Understanding these patterns allows businesses to adjust PIL calculations proactively, ensuring stock availability during peak seasons and avoiding overstocking during slower periods.

Graphical and qualitative forecasting

Graphical forecasting uses visual tools like charts to identify trends and patterns in historical data, while qualitative forecasting relies on expert judgment and market insights built up from years working in the industry.

Trend forecasting for long-term planning

Trend forecasting focuses on long-term demand changes driven by market shifts or consumer behavior. This proactive approach of integrating trend insights into PIL calculations ensures readiness for evolving customer preferences and reduces the risk of stock imbalances and holding costs.

Forecasting tools and techniques

Modern forecasting tools streamline inventory planning. Business intelligence (BI) and financial planning and analysis (FP&A) software, like Phocas, offers granular forecasting capabilities using sales history, customizable dashboards, and data integration to support accurate PIL calculations and overall inventory management.

Inventory forecasting methods

Effective inventory forecasting combines various methods such as lead time demand, safety stock analysis, and amount of inventory sold in various time frames to create a comprehensive plan. Leveraging multiple approaches ensures businesses maintain the right inventory levels.

Lead time demand is a key component

Lead time demand calculates the expected inventory required during the lead time period. This metric helps businesses align orders with anticipated consumption, minimizing stockouts and excess inventory.

Projected inventory levels are directly linked to demand forecasting, as they provide a snapshot of how current inventory, incoming orders, and anticipated sales align with future needs. The process also requires adapting to challenges like forecasting for new products without historical data and ensuring accurate predictions to balance inventory costs. A well-executed demand forecast ensures that resources are allocated efficiently to meet future sales expectations.

3 benefits of knowing projected inventory levels

With a powerful inventory management software that shows projected inventory levels and has built-in forecasting models, you’ll reap benefits across the entire company instead of just in the warehouse.

Customer satisfaction: Having a reliable technique to forecast means your warehouse will always have enough stock—helping customers avoid long waiting periods due to items being on back order. Brandon Gregory, the supply chain manager for American Metals Supply, knows the importance of PIL when it comes to customer satisfaction. “We’ve always been a disciplined and numbers-driven business, so we are spending a lot of time in Phocas building scorecards, running reports, and tracking AR and inventory…all of this will help us react quickly to the changing climate and the needs of our customers.”

Improved cashflow and savings: When you understand lifecycle and seasonal trends you learn what inventory is essential and what is collecting dust on the shelves, it becomes much easier to free up dollars by only purchasing the number of units needed.

Better supplier negotiations: Planning ahead is always beneficial, and that holds true when it comes to restocking inventory. When you have a better sense of what inventory you need in the future, it can help you partner with your suppliers to purchase the correct amount of materials and potentially arrive at a more favorable price point.

Pull all the pieces together with the right BI and FP&A solution

This increased visibility into the warehouse doesn’t have to come from just PIL. With a powerful business intelligence (BI) and financial planning and analysis (FP&A) solution like Phocas that integrates with your ERP, the optimization of inventory management is achievable. Leverage the solution to see how inventory is performing as a whole, or in more specific areas by breaking it down by sales channel or territory. Use it to free up cashflow in another way by gaining a clearer picture of what products are over or under-stocked, and how purchasing should be altered to fix it.

Phocas lets you dive into your data points and answer your questions. The BI and FP&A solution is designed so that anyone can pull meaningful information from the data they’ve already collected as well as carry out accurate forecasting. Share results throughout the company with customizable dashboards that make collaboration across the forecast period easy and informative.

Katrina is a professional writer with a decade of experience in business and tech. She explains how data can work for business people and finance teams without all the tech jargon.

Using data to plan for the impact of tariffs and further change

Tariffs are here. Whether you're in manufacturing, distribution or retail, it's important to understand how importing from affected countries such as Canada, Mexico or China or chosing local production, can affect your bottom line. We want to encourage you to scenario plan now not retrospectively.

Read more

The best financial KPIs for the distribution industry

Finance professionals in distribution businesses face a persistent challenge. That is to effectively blend operational and financial data to gain a complete picture of company performance. Traditional financial ratios often exist in isolation, making it difficult to assess the broader impact of operational decisions on financial outcomes.

Read more

Key sales KPIs for distribution companies

Managing sales in a distribution business without measuring key performance indicators (KPIs) is like maintaining your home without tools or a schedule. You don’t notice a leak until the damage is severe. Instead of making progress, you waste time searching for the right tools or calling an expert for simple fixes. Without the right KPIs, inefficiencies can go unnoticed, leading to cashflow issues and lost sales.

Read more

Essential KPIs every distribution company executive should measure

For mid-market leaders running a wholesale distribution business, data and business intelligence technology are crucial for monitoring financial and operational performance. However, the real value lies in how your team uses the data insights to influence decision-making.

Read more

Find out how our platform gives you the visibility you need to get more done.

Get your demo today